How the tubrocharger works, what is WasteGate and why is the bypass or blow-off valve needed?

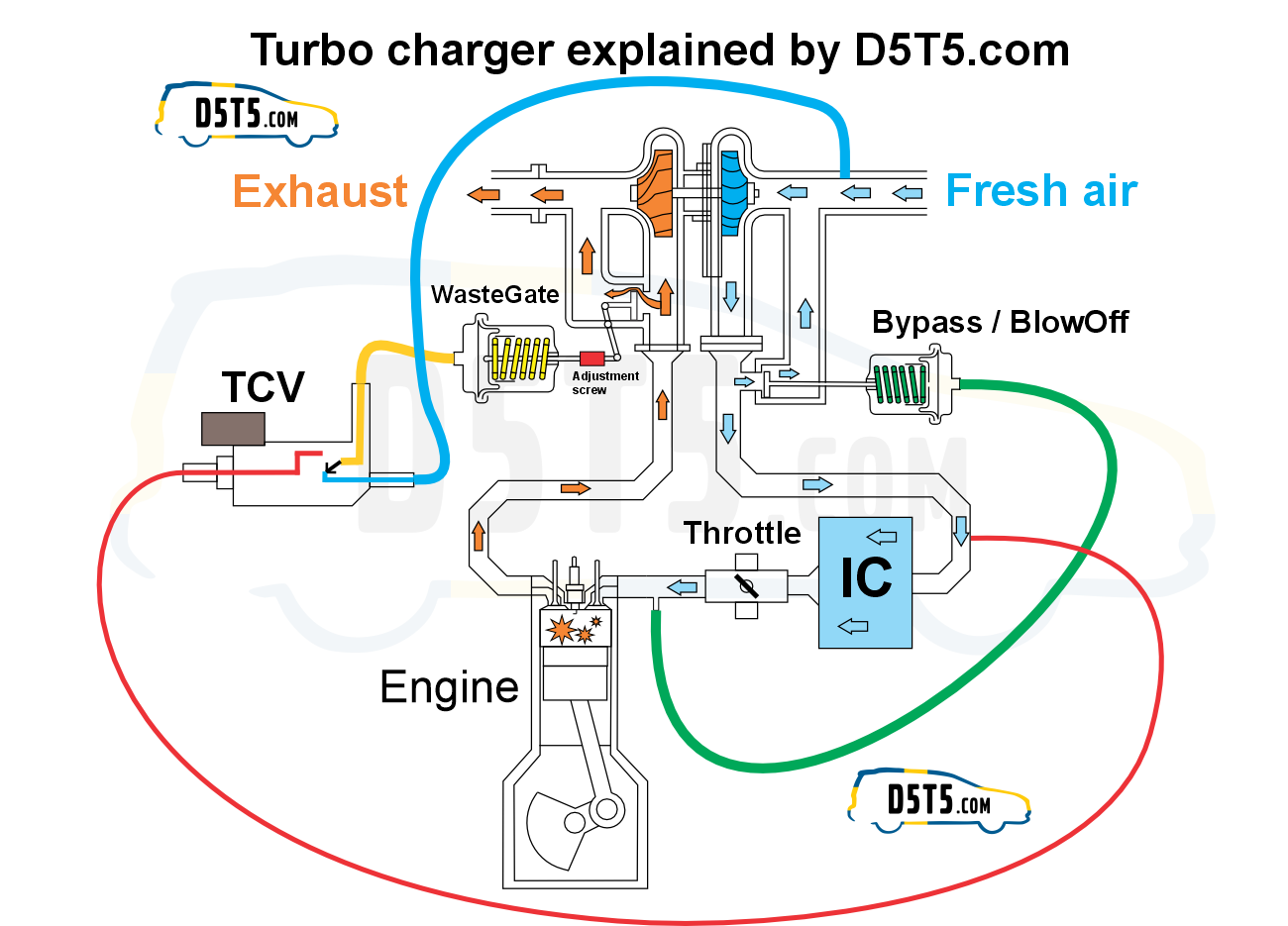

Below this text is basic schematic of turbocharger control. Of course, this may vary for some vehicles, so let's say it's like a 2005 Volvo V70 T5.

On the right side is the compressor section, where the turbo draws in fresh air, which is then compressed by the compressor turbine and moves past the blow-off/bypass valve—I'll explain that later—through the intercooler, where the compressed air cools down, then past the throttle valve, through the open intake valve, and into the engine's combustion chamber.

Here, fuel is added (if not already done so along the way) and ignited by a spark from the spark plug, causing an explosion. This pushes the piston down and rotates the crankshaft. As the piston moves back up, the exhaust valve opens, and the exhaust gases exit into the exhaust section and continue back to the turbocharger, where the hot exhaust gases spin the turbine. This exhaust turbine is connected by a shaft to the compressor turbine, creating pressure in the compressor section of the turbocharger.

That's a quick and simplified description. Now, let's talk about the basic regulation and protection of the entire system from uncontrolled operation.

On the intake or compressor side, we have a so-called bypass or blow-off valve. This valve releases excess pressure created when the throttle is released and the throttle valve closes. This typically happens when, for example, we need to change gears or stop. The turbocharger is spinning at this moment, and the compressor part is generating an air flow into the engine. However, when the throttle valve closes, this air is halted and has nowhere to escape. On the other side of the throttle valve, the engine wants to draw in air, creating a vacuum. This significant pressure difference could damage the throttle valve, blow out the pressure hoses before it, or damage the turbocharger without intervention. Hence, the bypass or blow-off valve, which is controlled by the vacuum created by closing the throttle valve between the engine and throttle valve, pulls on the membrane of the blow-off/bypass valve, connecting the compressor and intake chamber, drastically reducing the pressure before the throttle valve and preventing damage in the compressor section of the system. When the driver presses the accelerator, the throttle valve opens, the back vacuum disappears, and the bypass or blow-off valve closes again.

Behind the turbocharger, the situation is slightly different.

Before the exhaust turbine, there's a valve called a wastegate, which protects the exhaust turbine from destruction by excessive exhaust gas pressure, which could cause the turbine to exceed critical RPMs, potentially causing the turbine blades to break off, the bearing to seize, the shaft to bend, etc. Excessive turbocharger RPMs also cause high pressure in the compressor part, which isn't always desirable. The wastegate also acts as a turbocharger performance regulator.

For regulation, there's a TCV (Turbo Controll Valve) valve connected by hoses to the turbocharger's wastegate on the exhaust side, to the intake side before the turbocharger, and to the compressor part between the turbocharger and the throttle valve.

The TCV valve is a three-way valve that switches between pressure and vacuum, controlling the opening of the wastegate. This valve is electronically controlled, and its opening and closing are determined by the engine's control unit based on additional data from engine sensors and the throttle pedal.

The management of the wastegate is complex, and to simplify, we won't delve into it in detail here.

However, we're interested in where the most common faults in this control system occur.

- Leakage of the bypass/blow-off valve or damaged closure spring. If the spring or sealing surface holding the bypass/blow-off valve closed is damaged, air might start escaping back before the turbocharger or into the atmosphere. This reduces engine performance, and the engine won't perform as expected. This fault might end up triggering an engine error message. By blocking the original bypass valve and installing a blow-off valve, you can achieve that famous racing sound during gear shifts – example sound: https://youtube.com/shorts/NQAQW1A6hwo?si=fPfBM_F70iMMvK6g.

The difference between a blow-off valve and a bypass valve is that the bypass valve redirects excess pressure before the turbocharger, whereas the blow-off valve releases excess pressure out of the system into the atmosphere – which creates that famous racing sound. - Incorrect wastegate preload. If the preload pressure (the tension of the rod holding the wastegate closed) is too low, the wastegate may open when the engine control unit does not require it, and the exhaust gases meant to spin the exhaust turbine will escape into the exhaust. This results in a drop down pressure in the compressor part, and the engine won't achieve the desired performance. Preload is mechanically adjusted by shortening or lengthening the wastegate control rod by screwing the adjustment screw.

- Faulty TCV valve. If the wastegate preload is set correctly but the TCV valve isn't working properly, the wastegate may open when it shouldn't, reducing engine performance. Conversely, if the wastegate doesn't open when needed, the turbocharger may overspin, or, in a better scenario, trigger an error message about high boost pressure. The TCV valve controls the amount of gas passing through the exhaust turbine, directly affecting its RPMs and, consequently, the RPMs of the compressor turbine, and thus the pressure created in the compressor part.

- Deteriorated/leaking/perforated vacuum/pressure hoses from the TCV and blowoff valves. If any hoses controlling the TCV or blow-off valves are leaking, then the regulation won't work correctly, and the engine won't deliver the expected performance.

- Leaks in the intake hoses, intercooler, etc. If there's a leak anywhere in the system before or after the turbocharger, the system won't function correctly, and it won't deliver the expected performance due to the loss of air/exhaust gas pressure.

That's a simplified course in turbocharger regulation and a quick troubleshooting guide! I hope this sheds some light for many of you, perhaps helping you understand why your Volvo might not be performing as expected, or why you didn't feel a difference after a performance optimization loaded with VDASH from D5T5.com 😊